Boron Carbide Sandblasting Nozzle Set – 3 to 10mm Replacement Tips for Sandblaster Guns

Free shipping

Fast delivery

Description

HOLDWIN Boron Carbide Sandblasting Gun Nozzle

Features:

- Low density, high hardness and strength corrosion.

- Low thermal conductivity.

- Super duarable.

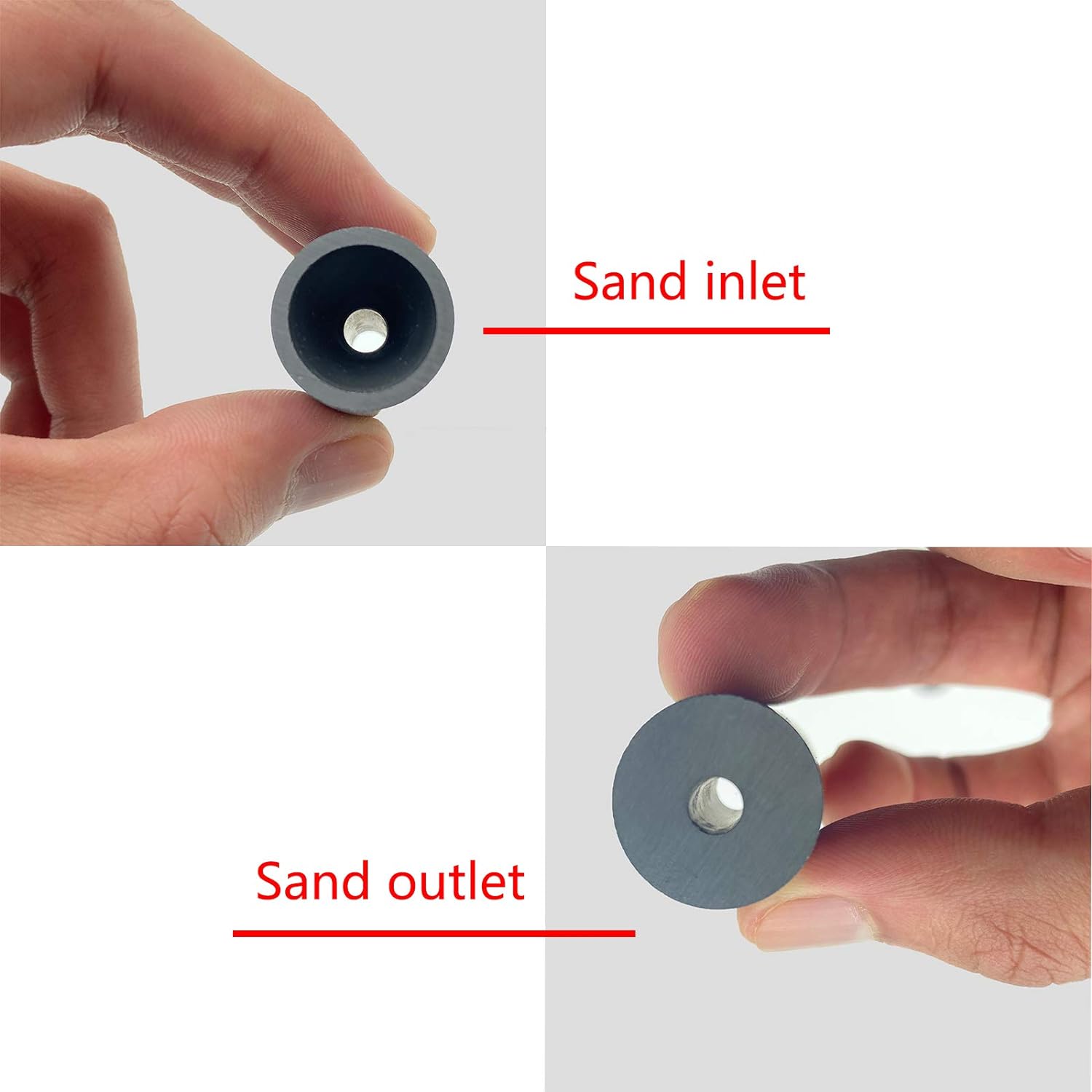

Benefits of Our Boron Carbide Nozzles:

► Saves money because you won't have to replace nozzles as often.

► Lasts longer than tungsten carbide nozzles while being less cost.

► Ensures a constant strong blasting stream because it holds up longer with the same inner diameter.

► Reduces fatigue on your air compressor caused by worn out nozzles which also saves money on your electricity bill and reduces the likelihood of replacing over-worked compressor parts.

► Reduces time in replacing nozzles so you can focus on getting the project done

Specification:

- Density: ≥2.48/cm3

- Microhardness: ≥3500kgf/mm2

- Flexural strength: ≥400MPa

- Melting point: 2450 ℃

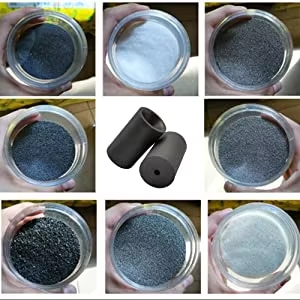

- Life for each material: Steel Shot: 2000-2500h, Quartz sand: 1000-1500h, Corundum: 500-1000h

- Material: Boron carbide

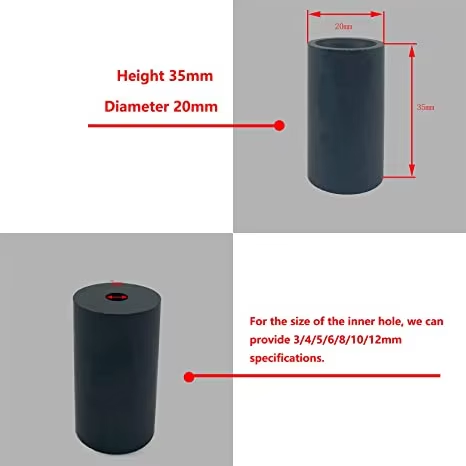

- Dimensions: 35x20mm/1.38x0.79inch

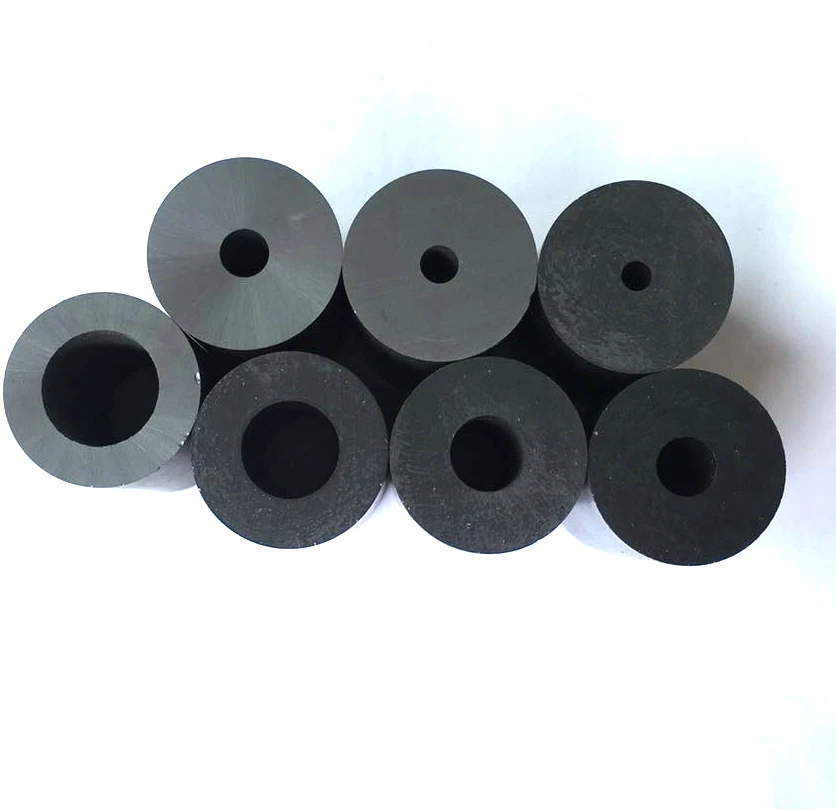

- Bore diameter: 3mm, 4mm

- Color: Black

- Quantity: 1 Pc

- Please allow 0-1 cm error due to manual measurement. pls make sure you do not mind before you bid.

- Due to the difference between different monitors, the picture may not reflect the actual color of the item. Thank you!

Package includes:

1) Length: 35 mm

2) Outer diameter(OD): 20 mm

3) Bore diameter(ID): 3/4/5/6/8/10/12 mm

You may also like

FAQ

These are the most frequently asked questions from our customers regarding our sandblasting accessories. Have any other questions? Please contact our customer support.

Our customer support hours are Monday to Saturday.

Average response time: 24 hours.

Does this helmet provide comprehensive protection and maintain visibility under prolonged abrasive operations?

Yes. The helmet is engineered to shield the entire head, face, and eyes from abrasive rebound and dust. It includes a replaceable visor to ensure sustained clear visibility during extended blasting sessions.

How is nozzle wear assessed, and what materials ensure optimal durability?

Nozzle wear is indicated by decreased blasting efficiency or visible erosion. Our nozzles are manufactured from high-durability ceramic or tungsten carbide to maximize lifespan under continuous abrasive conditions.

Are these gloves engineered for abrasion resistance and long-term operational safety?

Yes. Constructed from heavy-duty rubber with extended cuffs, the gloves protect hands and forearms from mechanical wear, abrasive media, and dust ingress, ensuring safe and reliable operation.

What are the operational specifications for pressure and compatible abrasive media?

The pneumatic sandblasting gun is compatible with standard compressors (typically 60–120 PSI) and supports a wide range of abrasive media including aluminum oxide, glass beads, silicon carbide, and steel grit, suitable for professional surface preparation.