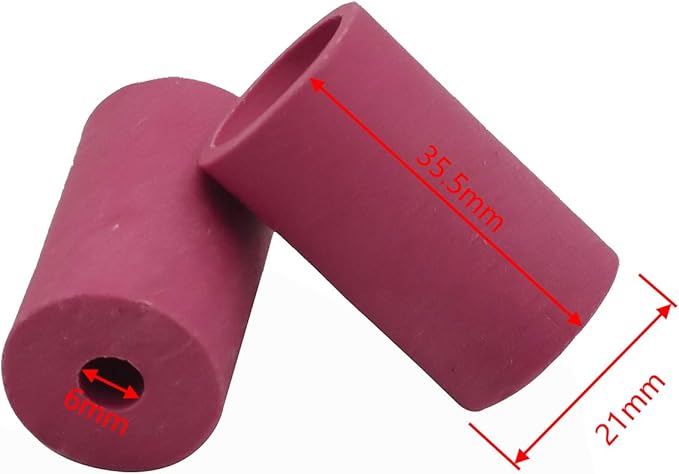

HOLDWIN 20-Pack Ceramic Sandblaster Gun Nozzles – Abrasive Blasting Replacement Tips

Free shipping

Fast delivery

Description

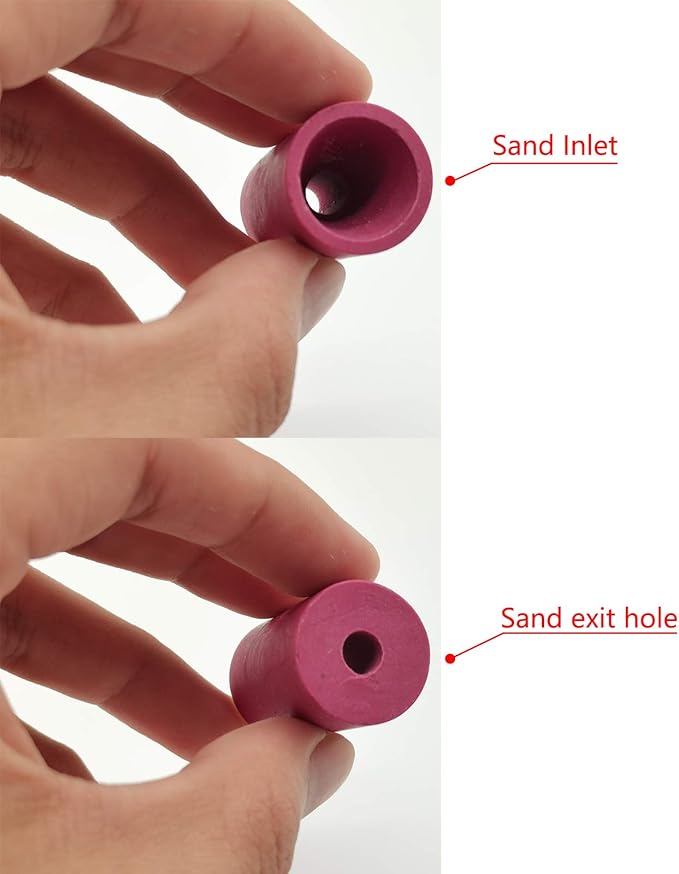

Product Description Mainly used for glass sandblasting, carving and other deep processing. Marble and other stone carving processing. It can also be used in machinery, metallurgy casting and other industrial machinery parts, casting surface sand cleaning, rust removal. It can replace cast iron and alloy steel sandblasting nozzle. Good performance, strong wear resistance, long life, high work efficiency, save steel, reduce costs. Ceramic tip.

Mainly used for glass sandblasting, carving and other deep processing. Marble and other stone carving processing. It can also be used in machinery, metallurgy casting and other industrial machinery parts, casting surface sand cleaning, rust removal. It can replace cast iron and alloy steel sandblasting nozzle. Good performance, strong wear resistance, long life, high work efficiency, save steel, reduce costs. Ceramic tip.

Portable Sandblasting Gun Kit

Sandblasting, or abrasive blasting removes the top surface layer of a material by using compressed air to direct abrasives toward the surface at high speeds.

Abrasive blasting erodes the surface, ridding it of paint, dirt, and other substances and prepares the surface for future treatments.

Features of ceramic sandblasting tip

-High-temperature resistance: can be used at high temperatures without being affected, high melting point, high boiling point

- Water absorption rate <0.2%.

-Bulk density 3.6-3.8g/cm3, solid texture, will not be affected by weather changes and humidity

-Corrosion resistance: not affected by a strong acid, strong alkali, inorganic salt, organic salt and other conditions.

Handheld pneumatic sandblasting gun special, universal tips

-Designed for efficient sandblasting and cleaning of parts and surfaces.

-Can be used for glass blasting, surface polishing process, mechanical parts treatment, etc.

-Cast aluminum pistol grip ensures a comfortable grip and long-time use.

-Suitable for cleaning car wheel stains and rust stains, removing rust from fences, refurbishing exterior masonry, etc.

Accept Versatile Medias

Sandblasting gun works with almost any blasting media including silica sand, garnet, crushed glass, mineral sands, coal slag, glass bead, crushed walnut shell, baking soda, aluminum oxide and etc. Choose your media for the desired job!

You may also like

FAQ

These are the most frequently asked questions from our customers regarding our sandblasting accessories. Have any other questions? Please contact our customer support.

Our customer support hours are Monday to Saturday.

Average response time: 24 hours.

Does this helmet provide comprehensive protection and maintain visibility under prolonged abrasive operations?

Yes. The helmet is engineered to shield the entire head, face, and eyes from abrasive rebound and dust. It includes a replaceable visor to ensure sustained clear visibility during extended blasting sessions.

How is nozzle wear assessed, and what materials ensure optimal durability?

Nozzle wear is indicated by decreased blasting efficiency or visible erosion. Our nozzles are manufactured from high-durability ceramic or tungsten carbide to maximize lifespan under continuous abrasive conditions.

Are these gloves engineered for abrasion resistance and long-term operational safety?

Yes. Constructed from heavy-duty rubber with extended cuffs, the gloves protect hands and forearms from mechanical wear, abrasive media, and dust ingress, ensuring safe and reliable operation.

What are the operational specifications for pressure and compatible abrasive media?

The pneumatic sandblasting gun is compatible with standard compressors (typically 60–120 PSI) and supports a wide range of abrasive media including aluminum oxide, glass beads, silicon carbide, and steel grit, suitable for professional surface preparation.