HOLDWIN High-pressure Sandblasting Cabinets for Old Paint Removal

Description

Product Details

High Pressure Sandblasting Machine Cabinet for Hard Paint Removal

High pressure blast cabinets are ideal for tough jobs where large surfaces or thick layers must be cleaned quickly. The conveying speed of the medium in the pressure cabinet is accelerated, and the peeling force is significantly increased.

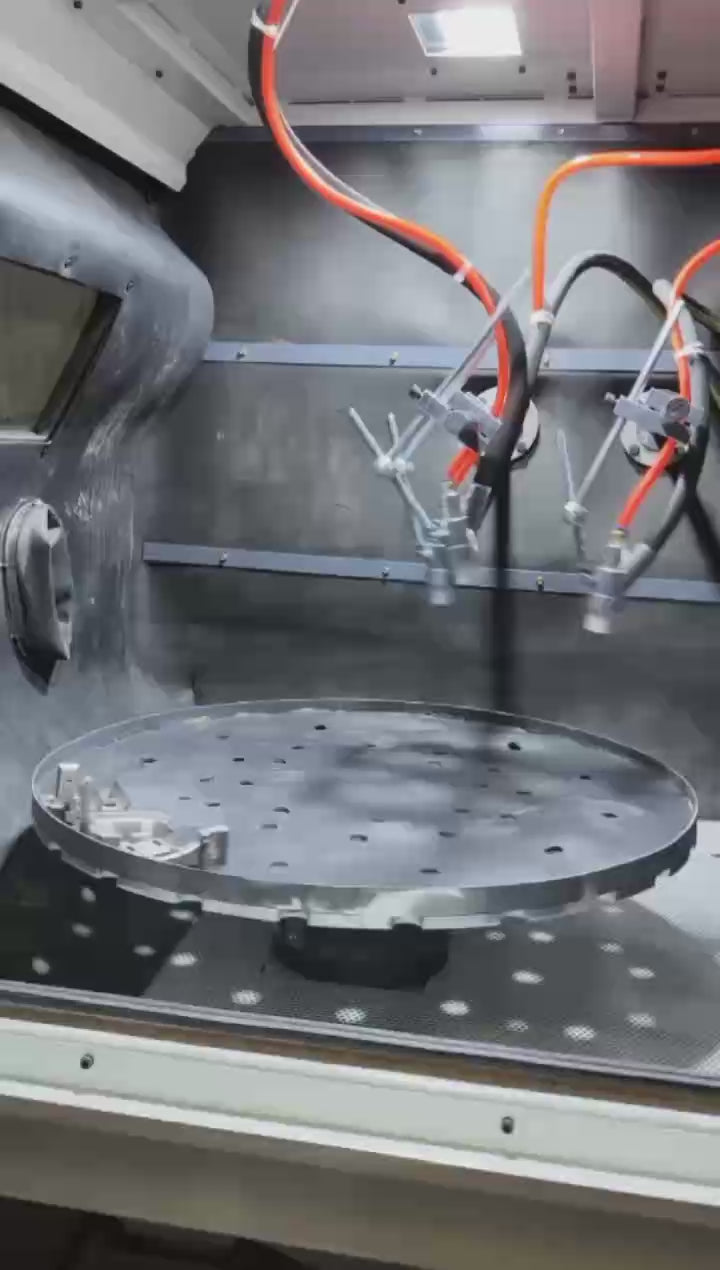

High-pressure sandblasters use a pressurized container to push the abrasive directly to the nozzle, where it is sprayed onto the surface of the part. This method speeds up abrasive delivery and produces more powerful cutting forces, making it ideal for tough cleaning jobs such as removing heavy burrs, sharp edges, and repainting that are difficult to vacuum. Pressure blasting machines are also ideal for handling hard materials such as alloy wheels, marble, stone, castings, auto parts, and more.

Pressure Blasting Cabinet Features

1. Cabinet design, enclosed type without dust and abrasive leakage, cause no pollution to environment and protect users' health.

2. Equipped with dust collector device ensures clear working condition inside the blasting cabinet

3. The abrasive in the storage tank can be recycled for many times, reducing consumption and save cost.

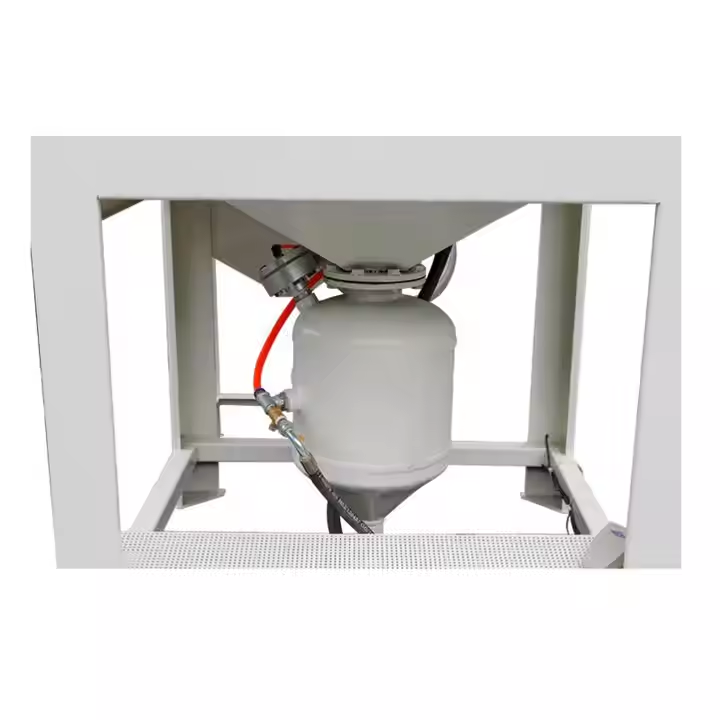

4. The advanced technology developed the pressure abrasive valve, improve processing quality, reduce the compressed air consumption.

5. The pressure blasting cabinet can be customized to installed with turntable or loading cart for heavy duty products

|

|

|

| Blast chamber | Blast gun | Pressure pot |

Product Parameters

|

Model

|

1010P

|

||

|

Work Chamber

|

L1000*W1000*H800mm

|

||

|

Outer size

|

L1650*W1200*H2100mm

|

||

|

Max loading

|

80~100kgs

|

||

|

Power Supply

|

110V/220V/380V/410V450V(50-60Hz)

|

||

|

Motor Power

|

0.55kw

|

||

|

Main Structure

|

Working chamber

Cartridge filter dust collector

Electric controll system

Pnuematic control system

Rotating Turtable

Loading Cart and track

|

||

|

Spare parts

|

Sandblasting gun with boron carbide nozzle

Air blowing gun

Blasting hose

Sandblasting gloves

|

Blasting Application

By using different blasting abrasives such as: glass beads, white corundum, steel ball, brown aluminum oxide, ceramic sand, etc. you can achieve various desired surface for subsequent procedure, such as :

- Remove scratches, improve roughness, clear the surface of all kinds of handicrafts, plastic, metal, furniture, decorative products.

- Descaling and refurbishing of casting parts, stamping pieces and heat treatment products by sand blast cabinet.

- Burnishing of all kinds of metal products, glass, plastic arts and crafts, jewelry, glasses, clocks and watches.

- Can be also used for pre-treatment process of electrostatic spraying and electroplating to enhance the adhesion of coating surface.

Tell us your products and finishing requirements, we will supply you a complete sandblasting solution.

This product has no reviews yet.