HOLDWIN 350L Box Type Sandblasting Machine Rust Removal Oil Removal and Paint Removal Equipment for cleaning

Description

Box Type Manual Sand Blasting Machine

Product Description

1. Mainly used in the surface treatment of the workpiece;

2. Sealed design of the box, automatic circulation of abrasive, more economical and environmentally friendly use;

3. The observation window is wide and transparent, and the box is equipped with fluorescent lamps, which is convenient for operation under various light conditions;

4. Open door design, convenient to take parts;

5. Plastic spraying inside and outside, 2mm thick steel legs (1.5mm thick box panel).

Advantages of the Equipment

1. Metal parts are basically undamaged and the dimensional accuracy will not change;

2. The surface of the parts is not polluted, and the abrasive will not have chemical reaction with the material of the parts;

3. It is easy to deal with the parts which are difficult to be contacted by grooves, and a variety of grain sizes of abrasives can be selected for use;

4. Processing costs are greatly reduced, mainly reflected in the improvement of work efficiency, can meet a variety of surface finishing requirements;

5. Low energy consumption and cost saving.

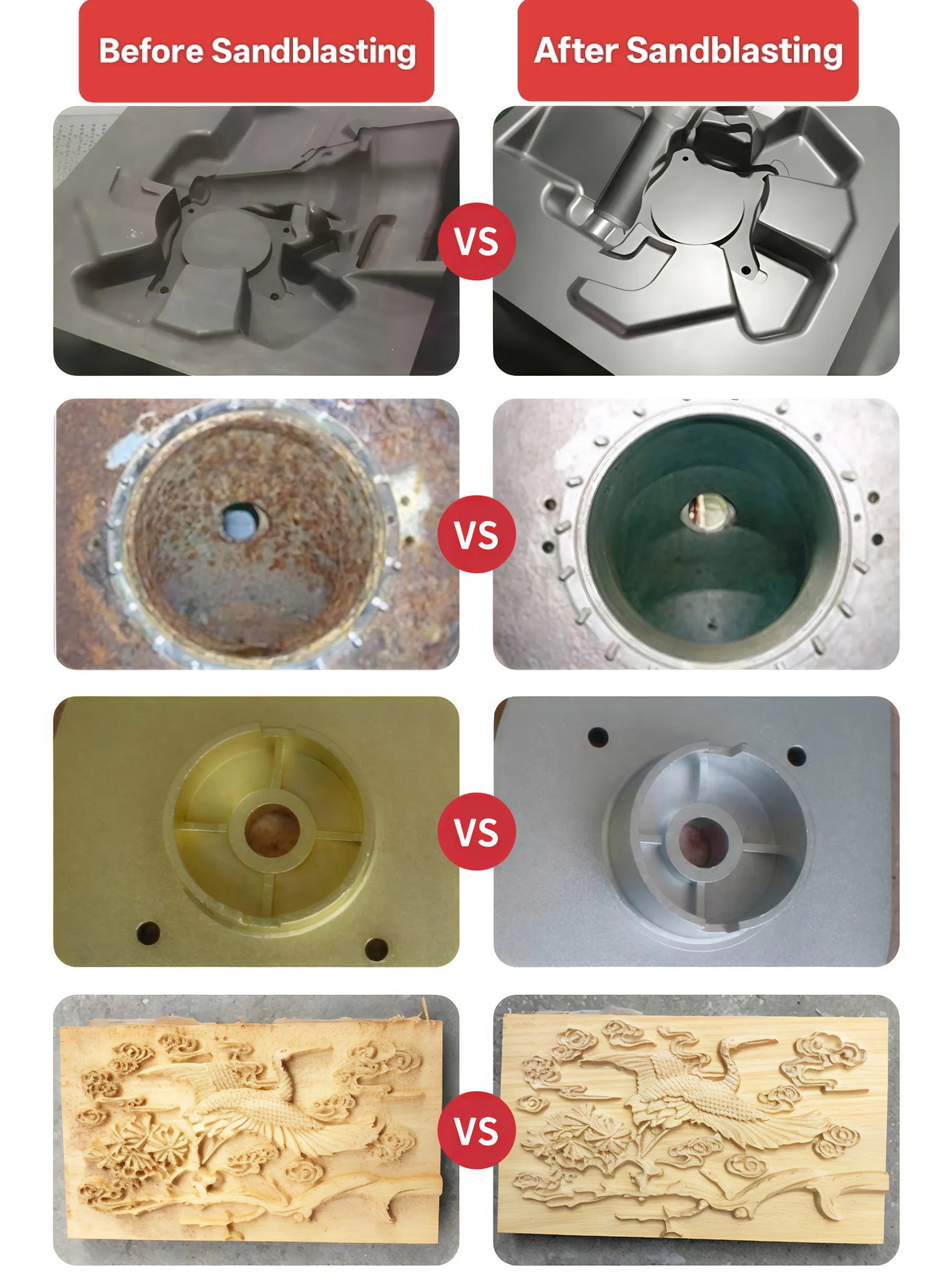

Scope of Application

The main use of sand blasting machine

1. Cleaning and strengthening of the outer surface of parts and components;

2. Cleaning and strengthening of tools and materials:

3. Surface cleaning of parts before plating, oxidizing and painting;

4. Removal of contaminants on the surfaces of barrels, tubes, plates, tanks and utensils;

5. Cleaning of tools, molds, tubes, plates and operating parts;

6. Surface cleaning of glass molds, rubber molds, metal castings and extrusions;

7. Trimming of weld seams;

8. Glazing of workpiece surfaces;

9. Removal of oxide skin on the surface of workpieces and removal of color differences produced during processing (castings, forgings);

10. Clean up large turbines, engine castings or complex small parts;

11. Cleaning of parts (such as cylinder blocks, pistons and spark plugs) during engine maintenance;

12. Cleaning the surface of brushes, contactors and wiring arts, etc., to improve electrical conductivity;

13. Parchment and other artwork cleaning and preservation;

14. Removal of old paint and dirt on the surface of workpieces, etc.

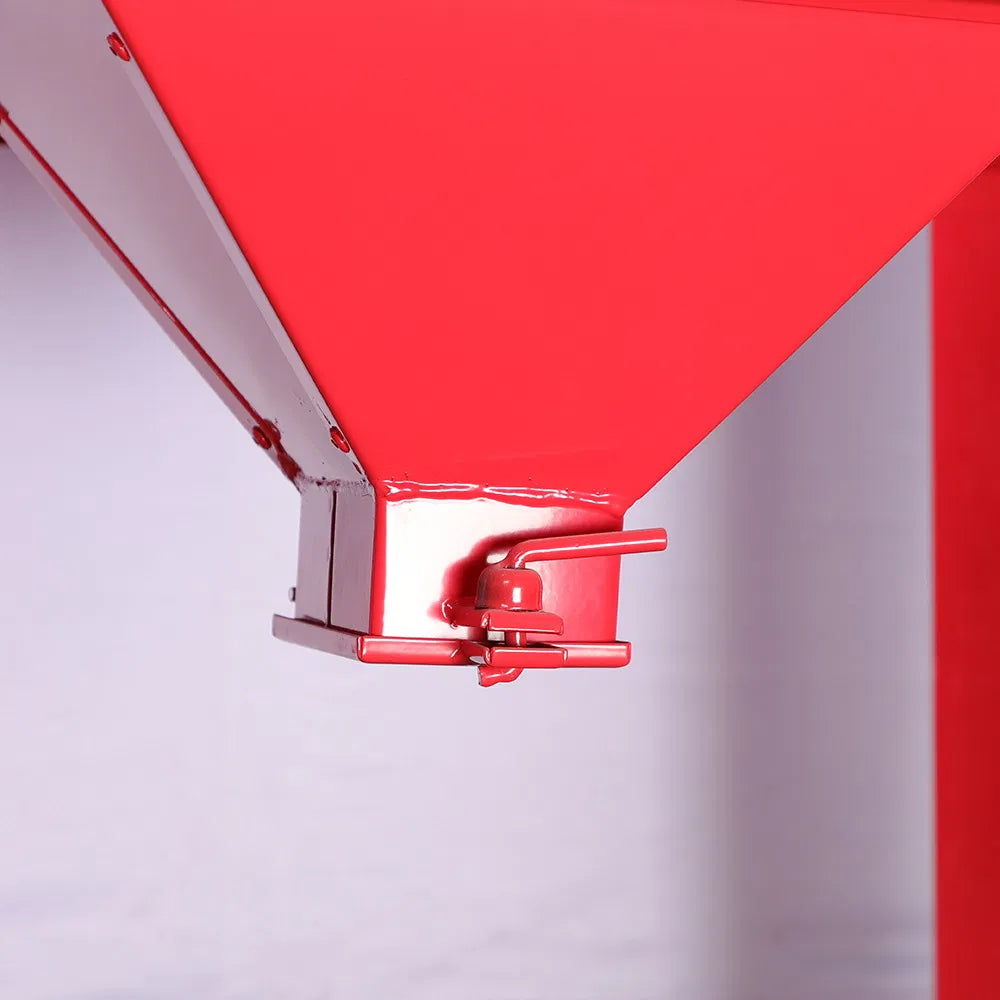

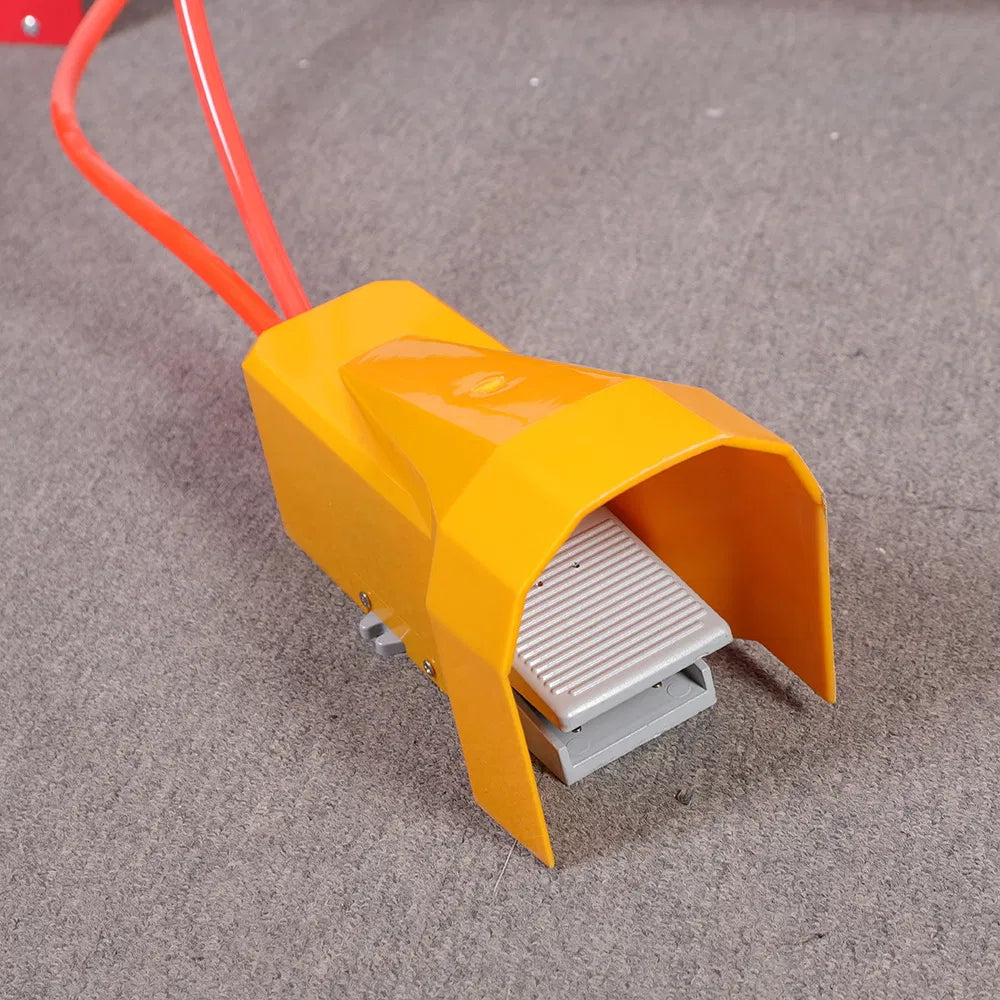

Detailed Photos

This product has no reviews yet.