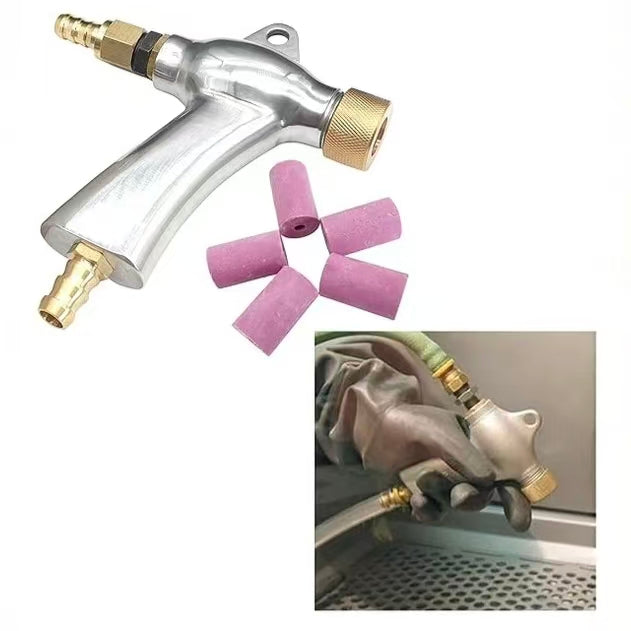

Heavy Duty Pneumatic Sandblaster Gun Kit with 6mm Ceramic Nozzles – 5 PCS

Free shipping

Fast delivery

Description

- 【Wide Range of Applications】: Specially used for polishing, spraying and polishing various dead ends of light metals and small metals, rough edges and rusty details as well as paint peeling, tiles, car surface treatment, glass etching, etc.

- 【Sand blasting Gun Material】: sandblaster gun is made of aluminum alloy, with good quality, high wear resistance and longer service life, making your work more efficient and convenient.

- 【Comfortable Grip】: The grip design is ergonomic, and the comfortable grip design of the sandblasting gun reduces the fatigue of the operator and improves the efficiency of long time blasting.

- 【Support A Variety of Blasting Media】: Suitable for (46-240#) purpose non-metallic blasting media, baking soda or glass beads, sodium bicarbonate, silica, walnut, garnet, etc. Please make sure to use the right abrasive for your project.

- 【Package Specifications】: 1 air blast gun, 1 ceramic tip. Tip: Please wear gloves and other protective equipment to ensure safe handling, and please do not point the blasting gun at people or animals.

Product description

Air Sandblaster Gun Blasting Gun for Sandblasting Cabinet for 990L/1200L Sand Blasting Cabinet Sandblaster Parts

Some of the reasons why the sandblasting gun can't run

1, whether the air compressor is suitable (our sandblasting gun needs an air compressor of 7.5 kW/10 hp or more).

2、Is the abrasive medium suitable (this product supports (46-240#) non-metal sandblasting materials, such as baking soda or glass beads, sodium bicarbonate, silica, walnut, garnet, etc.).

3、Is the pressure suitable, if your sandblasting cabinet has sandblasting pressure adjustment, you can also adjust the pressure size of the air compressor through the regulator.

4, whether the sand valve is clogged, sand blasting machine within the unselected abrasive size is not the same, which will form a sand valve clogging.

5, whether the abrasive is damp, an air compressor is with sandblasting gun deployment and essential equipment, air compressor compressed air will produce water so that the abrasive damp cohesion.

6, sandblasting tube is blocked, sandblasting tube because of its special structure is particularly simple to be blocked by foreign objects, sand storage cylinder abrasive whether it has been used up.

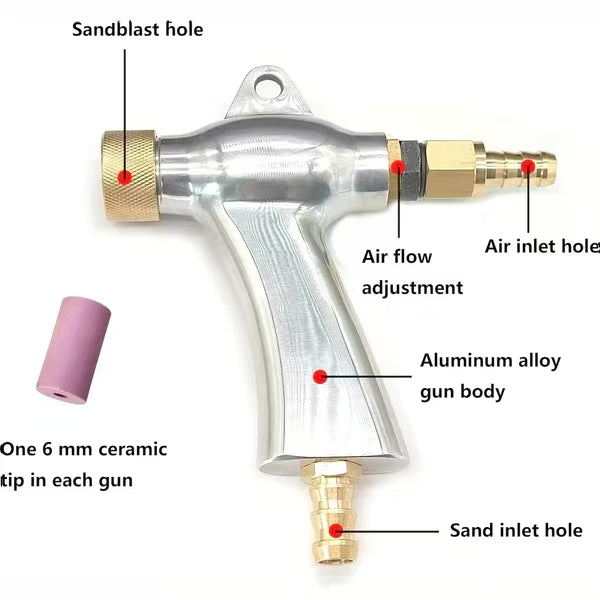

Adjustable air inlet thread clearance and ceramic tip

- You can adjust the distance to suit your work so that you can work more efficiently.

- The attached ceramic sandblasting nozzle allows you to complete your work evenly and effectively and can accept and spray various types of media, including sand (46-240#), alumina, silicon carbide, glass beads, etc.

Sandblasting gun partial details

The grip is ergonomically designed, Comfortable pistol-grip design reduces operator fatigue and increases productivity during prolonged blasting.

Comfortable grip

The hanging hole on the top of the gun body is convenient for you to place after use. The quick connector is made of brass, wear-resistant, convenient for installing air and sand pipes.

Comparison of sandblasting effect

Used in sandblasting, rust removal, polishing, and metal surface treatment, etc.

You may also like

FAQ

These are the most frequently asked questions from our customers regarding our sandblasting accessories. Have any other questions? Please contact our customer support.

Our customer support hours are Monday to Saturday.

Average response time: 24 hours.

Does this helmet provide comprehensive protection and maintain visibility under prolonged abrasive operations?

Yes. The helmet is engineered to shield the entire head, face, and eyes from abrasive rebound and dust. It includes a replaceable visor to ensure sustained clear visibility during extended blasting sessions.

How is nozzle wear assessed, and what materials ensure optimal durability?

Nozzle wear is indicated by decreased blasting efficiency or visible erosion. Our nozzles are manufactured from high-durability ceramic or tungsten carbide to maximize lifespan under continuous abrasive conditions.

Are these gloves engineered for abrasion resistance and long-term operational safety?

Yes. Constructed from heavy-duty rubber with extended cuffs, the gloves protect hands and forearms from mechanical wear, abrasive media, and dust ingress, ensuring safe and reliable operation.

What are the operational specifications for pressure and compatible abrasive media?

The pneumatic sandblasting gun is compatible with standard compressors (typically 60–120 PSI) and supports a wide range of abrasive media including aluminum oxide, glass beads, silicon carbide, and steel grit, suitable for professional surface preparation.